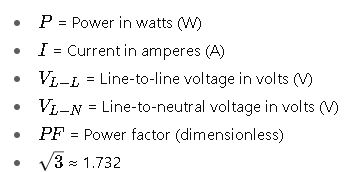

Watts to amps formula: DC A = W ÷ V. Single-phase AC A = W ÷ (V × PF). Three-phase A = W ÷ (√3 ≈ 1.732 × V × PF).

How to convert fast: divide watts by voltage (add PF, and √3 for three-phase). Examples: 1800 W @ 120 V, PF 0.9 → 16.7 A; 2000 W DC @ 24 V → 83.3 A.

Amps to Watts Calculator (A → W)

How do I convert amps to watts?

Single-phase (L–N) or L–L: W = V × A × PF.

Three-phase (L–L): W = √3 × V × A × PF.

What power factor should I use?

Which voltage should I pick (L–N vs L–L)?

Why do my watts differ from the nameplate?

Conversion Formulas and Detailed Explanations

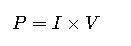

1. Direct Current (DC) Circuits

In DC circuits, the power (P) in watts is calculated using the formula:

Where:

- P= Power in watts (W)

- I= Current in amperes (A)

- V= Voltage in volts (V)

This formula assumes a power factor (PF) of 1, as DC circuits typically have a PF of 1 due to their purely resistive nature.

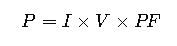

2. Alternating Current (AC) Circuits

a. Single-Phase AC Circuits

For single-phase AC circuits, the power is calculated as:

Where:

- P= Power in watts (W)

- I= Current in amperes (A)

- V= Voltage in volts (V)

- PF= Power factor (dimensionless)

The power factor accounts for the phase difference between voltage and current, which varies depending on the type of load.

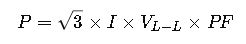

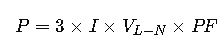

b. Three-Phase AC Circuits

In three-phase AC circuits, the power calculation differs based on the voltage type:

- Line-to-Line Voltage:

- Line-to-Neutral Voltage:

Where:

These formulas are crucial for accurately determining power in industrial and commercial electrical systems.

Amps to Watts Conversion Tables

Below are detailed conversion tables for various voltages and power factors, aiding in quick and accurate calculations.

DC Circuits

| Current (A) | Voltage (V) | Power (W) |

|---|---|---|

| 1 | 5 | 5 |

| 2 | 5 | 10 |

| 3 | 5 | 15 |

| 4 | 5 | 20 |

| 5 | 5 | 25 |

| 1 | 12 | 12 |

| 2 | 12 | 24 |

| 3 | 12 | 36 |

| 4 | 12 | 48 |

| 5 | 12 | 60 |

| 1 | 24 | 24 |

| 2 | 24 | 48 |

| 3 | 24 | 72 |

| 4 | 24 | 96 |

| 5 | 24 | 120 |

Single-Phase AC Circuits (PF = 1)

| Current (A) | Voltage (V) | Power (W) |

|---|---|---|

| 1 | 120 | 120 |

| 2 | 120 | 240 |

| 3 | 120 | 360 |

| 4 | 120 | 480 |

| 5 | 120 | 600 |

| 1 | 240 | 240 |

| 2 | 240 | 480 |

| 3 | 240 | 720 |

| 4 | 240 | 960 |

| 5 | 240 | 1200 |

Three-Phase AC Circuits (Line-to-Line Voltage, PF = 1)

| Current (A) | Voltage (V) | Power (W) |

|---|---|---|

| 1 | 240 | 415 |

| 2 | 240 | 830 |

| 3 | 240 | 1245 |

| 4 | 240 | 1660 |

| 5 | 240 | 2075 |

| 1 | 480 | 830 |

| 2 | 480 | 1660 |

| 3 | 480 | 2490 |

| 4 | 480 | 3320 |

| 5 | 480 | 4150 |

Note: These tables assume a power factor (PF) of 1 for simplicity. For loads with different power factors, adjust the power values accordingly.

Real-World Applications and Calculations

1. Residential Circuit Load Calculation

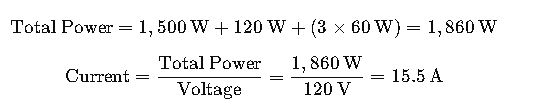

Scenario: A homeowner wants to determine if a 15-amp, 120-volt circuit can safely handle the combined load of a hairdryer (1,500 W), a vent fan (120 W), and three 60-watt light bulbs.

Calculation:

Since the circuit is rated for 15 amps, the combined load exceeds the circuit’s capacity, posing a risk of overload.

Recommendation: Use a 20-amp circuit to safely accommodate the total load.

2. Industrial Motor Power Consumption

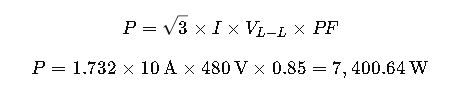

Scenario: An industrial motor operates at 10 amps on a 480-volt, three-phase system with a power factor of 0.85. Calculate the power consumption.

Calculation:

The motor consumes approximately 7.4 kW.

Practical Considerations for Electrical Professionals

- Power Factor Awareness: Always consider the power factor when calculating power in AC circuits, as it significantly affects the total power consumption.

- Safety Margins: Apply a safety margin (typically 20%) to prevent circuit overloads and ensure reliable operation.

- Code Compliance: Adhere to local electrical codes and standards, such as the NEC (National Electrical Code), to ensure safety and compliance.

- Equipment Ratings: Verify the amperage and voltage ratings of equipment to prevent overloading circuits and ensure proper sizing.

1. Residential Electrical Load Management

In residential environments, electrical panels are rated by amperage, which dictates the total load that can be safely supported. Homeowners often underestimate the cumulative power drawn by multiple appliances operating simultaneously.

For instance, consider a kitchen setup with a refrigerator, microwave, dishwasher, and lighting system. While each device may individually fall below the circuit’s ampere limit, their simultaneous operation could exceed safe capacity. Evaluating the total load in watts ensures that wiring, breakers, and outlets are sized correctly to prevent overheating, tripping, or fire hazards.

Proper load management also extends to energy efficiency. By understanding the wattage associated with specific amperage and voltage, homeowners can optimize usage schedules, avoiding peak demand periods that may result in higher electricity costs.

2. Industrial Equipment and Motors

In industrial settings, large machinery, conveyor systems, and motors require precise calculations of power consumption. Understanding the wattage drawn by equipment informs decisions about wiring size, transformer capacity, and protective devices.

For example, a three-phase motor powering a conveyor may operate intermittently with varying loads. Engineers calculate the maximum possible watts drawn under peak operation to ensure the electrical distribution system can accommodate sudden surges. This approach prevents voltage drops that can compromise equipment performance, ensures compliance with safety standards, and extends the lifespan of machinery.

3. Renewable Energy Systems

Solar and wind power installations rely heavily on accurate amp-to-watt conversions. Panels and inverters are rated based on maximum current and voltage outputs. Converting these values to watts helps in:

- Determining system efficiency

- Sizing inverters and charge controllers

- Designing battery storage solutions

For instance, a solar array delivering 10 amps at 48 volts needs proper evaluation of wattage output to match the inverter’s capacity and avoid overloading the system.

4. Electric Vehicle (EV) Charging Stations

EV charging stations are another scenario where amp-to-watt calculations are crucial. Different charging levels—Level 1, Level 2, and DC fast charging—demand precise assessment of power delivery. Knowing the wattage allows engineers to ensure:

- Circuit breakers are appropriately rated

- Charging times are predictable for users

- Thermal management systems are sufficient to prevent overheating

For example, a Level 2 charger delivering 32 amps at 240 volts requires a total wattage calculation to ensure the supply infrastructure and connectors can handle the load continuously.

5. Data Centers and IT Infrastructure

In data centers, servers and networking equipment draw high currents continuously. Understanding amps and their conversion to watts ensures:

- UPS (Uninterruptible Power Supply) units are correctly sized

- Cooling systems are adequate to dissipate heat

- Redundant circuits prevent downtime

Monitoring real-time wattage consumption allows facility managers to optimize energy usage, reduce operational costs, and maintain uptime for critical IT infrastructure.

Tips for Practical Implementation

- Regular Monitoring: Continuously track both amperage and wattage to detect inefficiencies or potential overloads.

- Circuit Labeling: Clearly label circuits with maximum wattage capacity to prevent misuse.

- Load Balancing: Distribute high-wattage devices across multiple circuits to avoid overloading a single line.

- Preventive Maintenance: Ensure all electrical connections, wires, and protective devices are inspected regularly for wear and tear.

- Energy Efficiency: Use amp-to-watt awareness to identify opportunities for energy-saving measures, such as replacing older appliances with high-efficiency alternatives.